Lift Station Packages for Wastewater Applications

Fiberglass Reinforced Polymer (FRP) Lift Stations by GWI

Customized

Lift Stations

GWI's packages are built to move as little as 20gpm to as much as 10,000gpm— at depths ranging from 4 feet to 50 feet.

Corrosion Resistant

Fiberglass wells from GWI resist damage from toxic gases such as Hydrogen Sulfide (H2S) due to the corrosion resistant isophthalic polyester resin used in their construction.

Effortless Installation

GWI is proud to have an available stock of inventory to provide quick turnarounds. Lightweight FRP wet wells have a simple installation process, and we can complete most installations within a day or two.

Customizable Lift Station Packages by GWI

Made to Fit Your Specific Needs

At GWI, we believe in making products that suit your needs perfectly. To this end, we created a team and facility dedicated to engineering and fabricating packaged lift stations. With specifications from as little as 20gpm to as much as 10,000gpm, we are ready to build a lift station that is tailor fit to your application.

Custom Controls

Simultaneously, GWI employs a team of experts and engineers who will customize your lift station controls to match the exact needs of your application. Our offerings include custom UL508A and 698A control panels, submittal packages, and control panels from other manufacturers, such as Primex, Stacon, and Dublin Automation. In addition, we provide odor controls by Pure Air Filtration to help cut down on unwanted odors. For higher efficiency, GWI offers Variable Frequency Drives (VFD) and remote monitoring by Grundfos to help protect your lift station pump.

Pump Selection

Our selection of submersible pumps, grinder, chopper, and solids handling pumps from premier pump manufacturers gives you flexibility and confidence. Our Grundfos and Zoeller wastewater pump lines are reliably made to handle the tough lift station environment. Partner with GWI to design the perfect match for your application.

Talk to an Expert

GWI’s Solution to Lift Station Corrosion

FRP Wet Wells from GWI

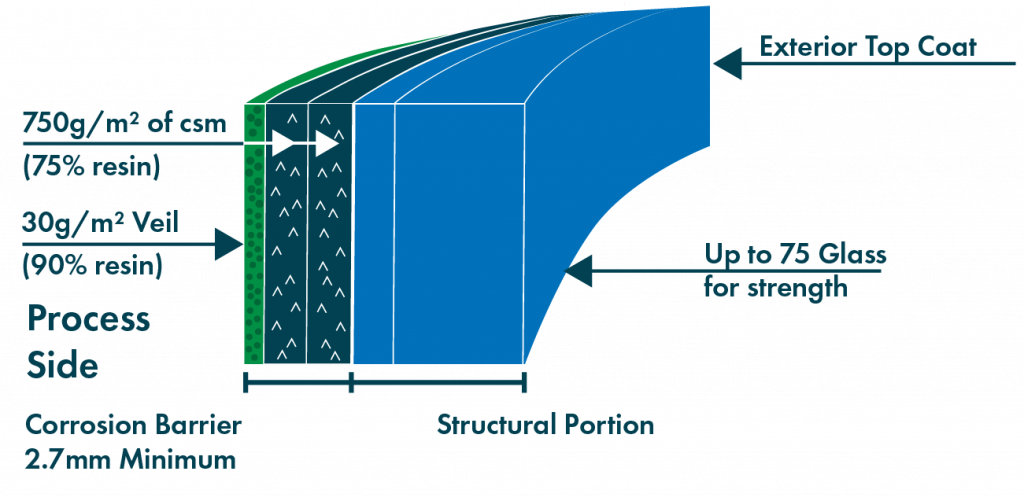

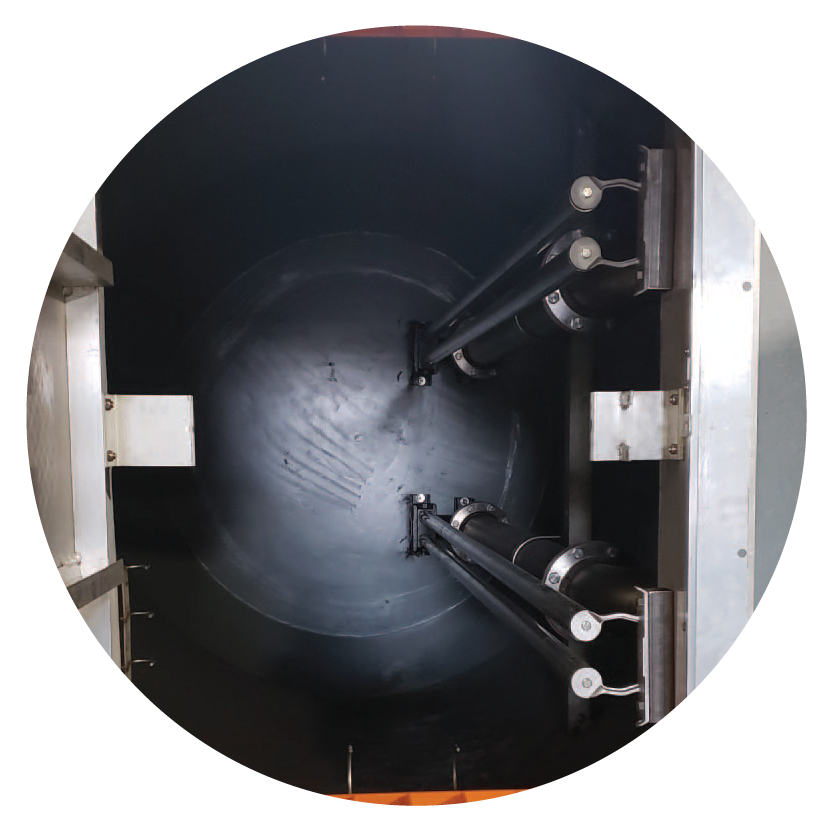

Maintaining a wastewater lift station has always included managing corrosion. With Fiberglass Reinforced Polymer (FRP) wet wells from GWI, however, managing corrosion in lift stations is a thing of the past. Our FRP products have been proven to have extraordinary corrosion resistance to common wastewater gases and acids, such as hydrogen sulfide and sulfuric acid. This makes managing wet wells easier and less costly for our clients.

FRP vs Concrete

Fiberglass (FRP) wells from GWI bring higher long term cost savings versus concrete wells. Comparatively, fiberglass has significantly more corrosion resistant properties that help maintain the structure without the need for regular maintenance. As a matter of fact, Hydrogen sulfide (H2S) or sulfuric acid, a common wastewater toxin, does little to no damage to our FRP wells over time. With FRP lift stations from GWI, you won’t need to worry about managing concrete wet well corrosion with costly and inconvenient maintenance like the routine application of protective coatings.

Quality Assurance

At GWI, we feel that actions speak louder than words. To this end, we have a put a 20 year warranty on all of our wet wells. We also include piping and elbows made of 316 stainless steel in the warranty. Now you can buy with confidence. Your goals are our goals. We stand behind our product and our customers in the quest to achieve maximum longevity for their lift stations.

Install Lift Stations Easily with GWI

GWI Makes Installation Easy

Another one of FRP’s advantages over concrete wells is its light weight. The entire fiberglass well and stub-outs we provide are fabricated at the plant. In effect, installation is a simple drop and go process. FRP is easier to lift and control during installation versus the more bulky alternative concrete. In essence, your installation will be a quick and seamless process which will save you time for more important matters.

Extra Time and Money for Concrete

Additionally, Bulky alternatives such as concrete from other companies are expensive to install. Concrete wells must be installed one section at a time and need to be sealed properly to ensure that they don’t leak. Moreover, the installation of pipe stub-outs for concrete wells is burdensome; it’s a tricky process that requires even more precious time. Our FRP packaged lift stations come with the pipe stub-outs pre made with the piping, valves, and floats already assembled and ready to go. With this in mind, making the choice to use GWI to fabricate your next lift station will certainly save time and extra costs.

H-20 Load Rating

Naturally, when making the switch to fiberglass lift stations the question whether the fiberglass is strong enough to handle the weight comes up. Well, our fiberglass wet wells carry an ASTM D3753 rating. This means our wet wells carry a H-20, or HS-20, load rating making them suitable for most any traffic situation where it can handle a wheel load of up to 32,000lbs.