LIFTLOGIC

Pre-engineered Lift Station Control Panels by GWI

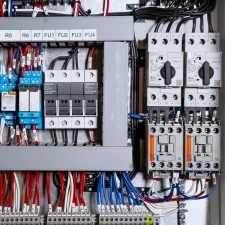

LiftLogic control panels are off-the-shelf simplex and duplex lift station panels designed to function with any brand of pump’s thermal and seal fail sensor. These UL 508A certified LiftLogic panels are designed to manage 3-phase voltages up to 25 amps per pump. Optional remote monitoring, a variety of level sensor inputs, and other customizable options are available – learn more.

LiftLogic Panels will ship within a week of receiving a purchase order.

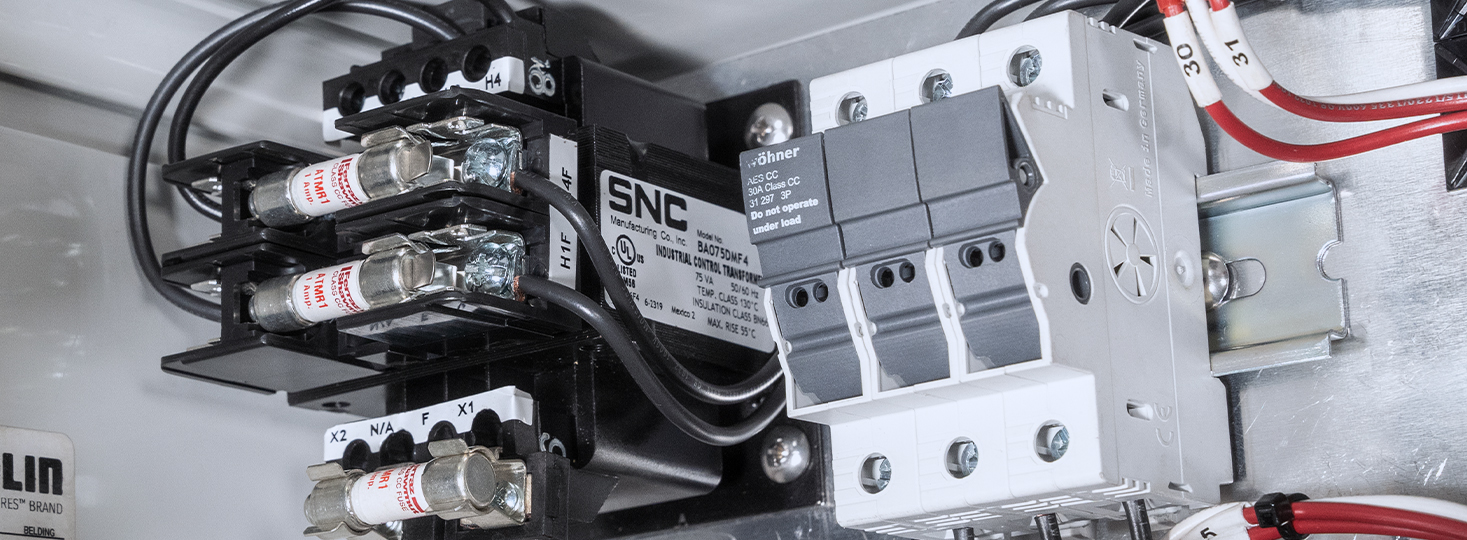

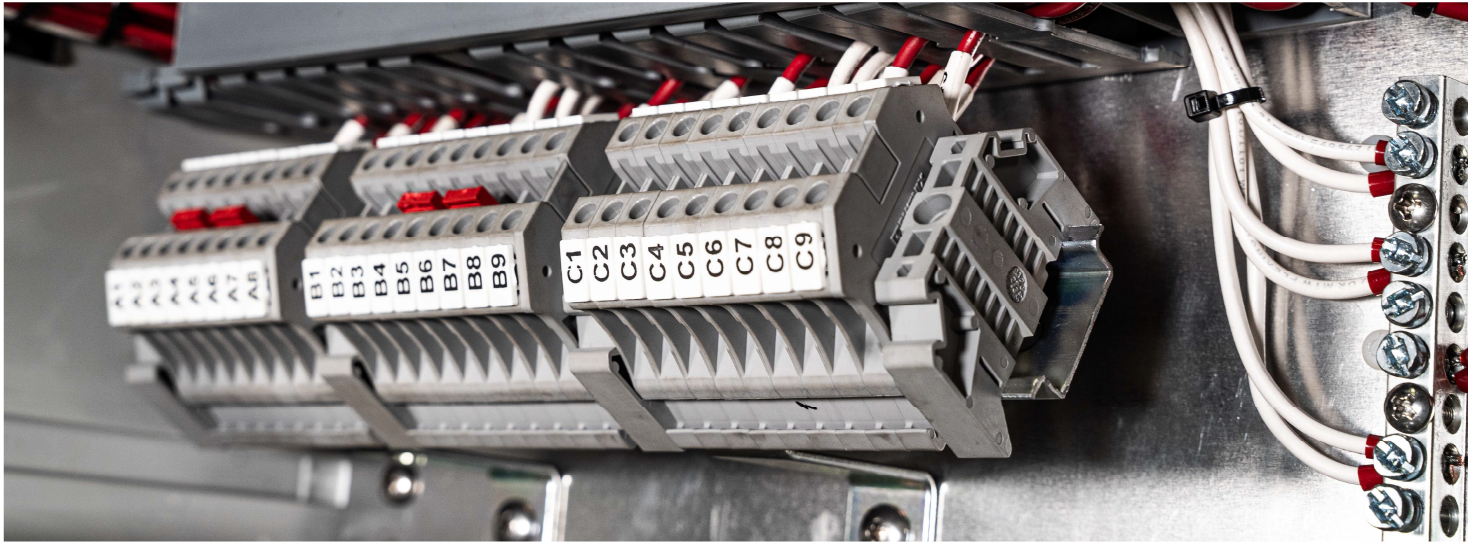

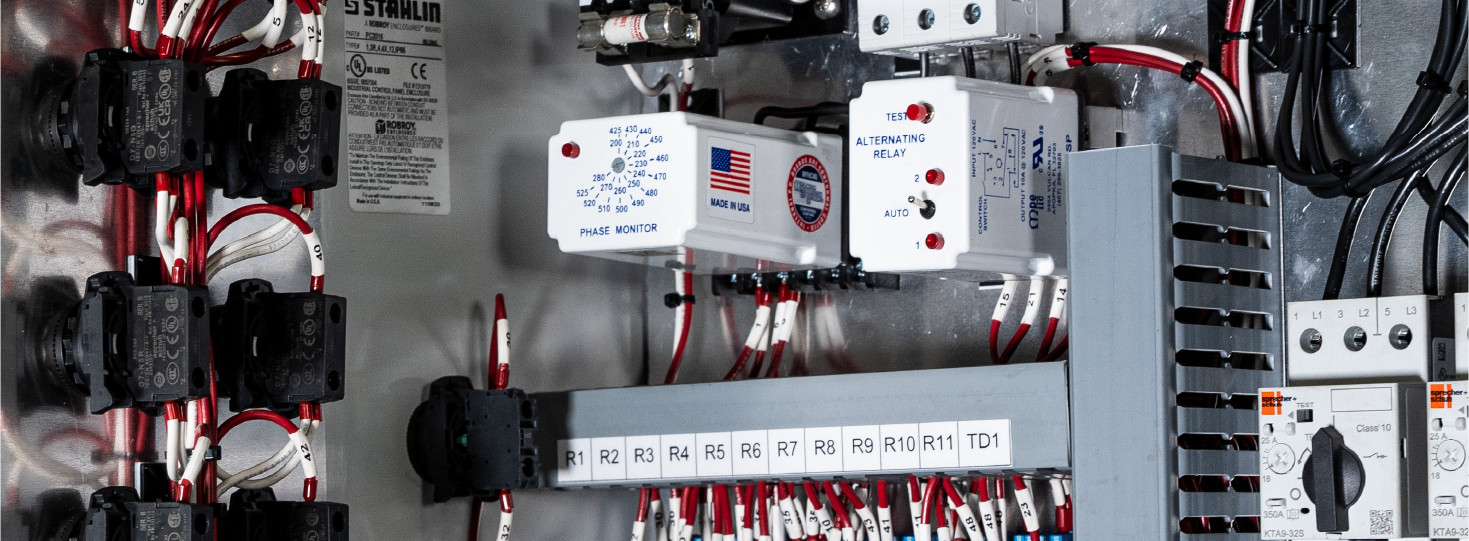

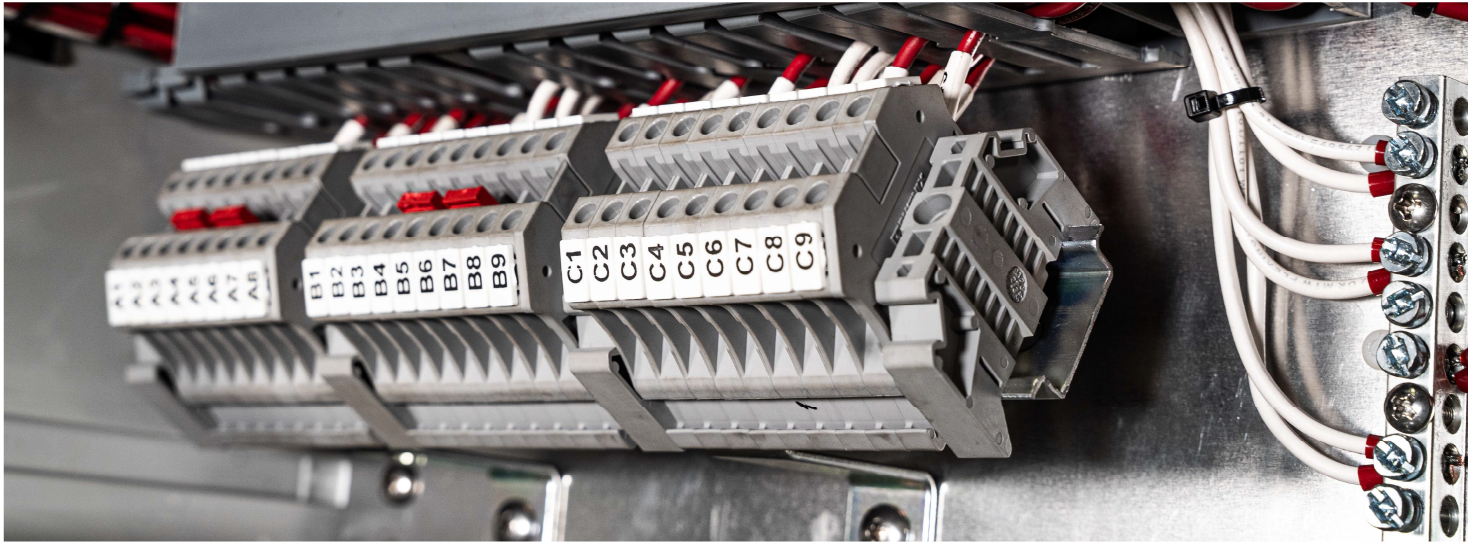

Made With Quality Parts

LiftLogic Standard

- Universal/Thermal Seal Fail Monitoring For Any Pump Brand

- Alternating Relay for Simplicity and Low Cost

- Lead Pump Select Feature

- Universal 3-Phase Input Voltage

- UL 508A Labeled Panel

- 4-Float Panel

- Float Failure Logic

- Simplex or Duplex Configuration up to 25A

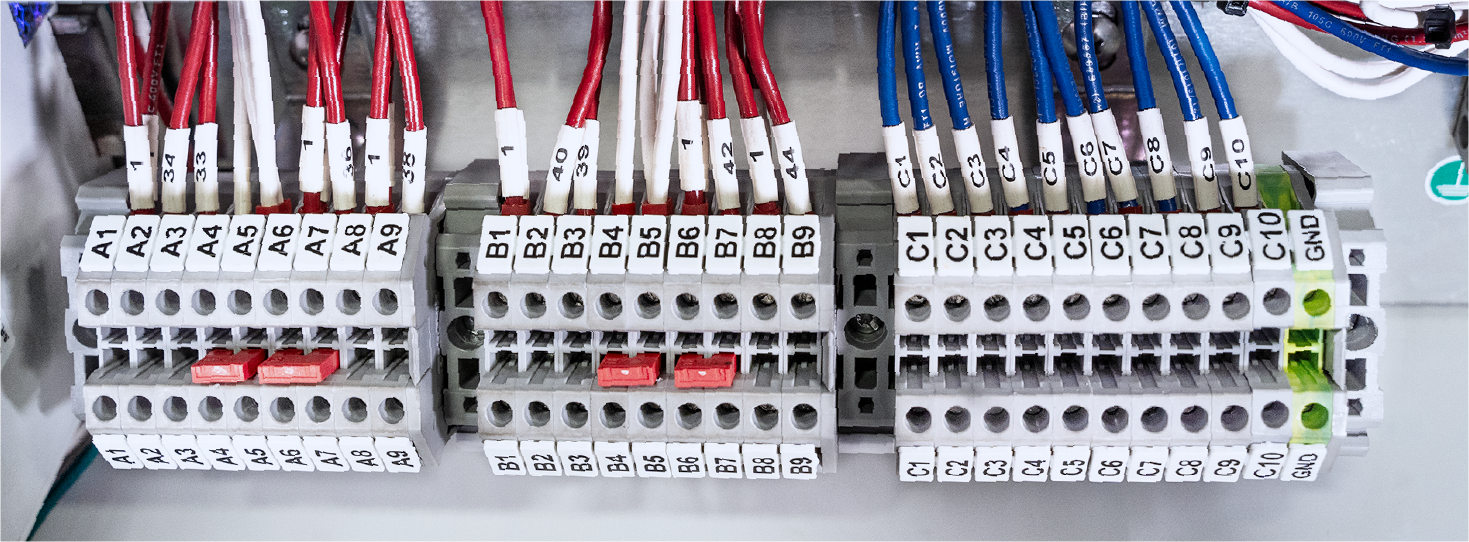

- Angled Din Rail for Easy Field Wiring

- NEMA 4X Rated

- Polycarbonate Enclosure with Dead Front Door

- 22mm Hand-Off-Auto Switches (Not Toggle Switches)

- Alarm Light and Horn (Silence Push Button Included)

- High Level Dry Contact for SCADA Connection

- Stainless Steel Enclosure Upgrade

- Phase Monitor

- Thermal & Seal Fail Monitoring for Flygt Pumps

- Surge Protective Device

- Elapsed Time Meters

- Level Lights

- Pump Run and Pump Fail Dry Contacts for SCADA

LiftLogic Intelligent

- Universal Thermal/Seal Fail Monitoring For Any Pump Brand

- Grundfos LC 241 Controller Packed with Features

- Bluetooth Connection via Free App

- Simple Configuration Changes Using App

- Alarm Diagnostics on Screen

- Universal 3-Phase Input Voltage

- UL 508A Labeled

- Compatible with Many Level Devices (Device Types)

- Angled Din Rail for Easy Field Wiring

- Simplex or Duplex Configurations up to 25A

- Circuit for High Level Backup Float

- NEMA 4X Rated

- Built-in Phase Monitoring

- Polycarbonate Enclosure with Dead Front Door

- 22mm Hand-Off-Auto Switches (Not Toggle Switches)

- Alarm Light and Horn (Silence Push Button Included)

- High Level Dry Contact for SCADA Connection

- Stainless Steel Enclosure Upgrade

- Thermal & Seal Fail Monitoring for Flygt Pumps

- Surge Protective Device

- Elapsed Time Meters

- Remote Monitoring with Grundfos Connect

- Pump Run and Pump Fail Dry Contacts for SCADA

Download The LiftLogic Product Sheet

LiftLogic Standard Features

LiftLogic Control Panels are designed to monitor and prevent thermal and seal failures for any pump manufacturer. This feature will prevent you from voiding your pump’s warranty and keep your pump from critically failing. The LiftLogic design simply requires jumpers to be correctly placed for your specific manufacturer.

*For Flygt pumps, LiftLogic panels will require a slight increase in lead time and price due to additional required components.

LiftLogic Control Panels seamlessly accommodate any of the three common 3-phase voltages: 208V, 230V, or 460V. The panels ensure effortless integration into any power system, providing the flexibility you need for smooth and efficient lift station operation.

Dry contact wired to terminal blocks for high level indication to customer SCADA system.

LiftLogic Intelligent Panels are engineered to receive nearly every type of level device that is commonly used, including:

- Radar Level Sensors

- Float Switches

- Ultrasonic Level Sensors

- Pressure Transducers

*LiftLogic Standard Panels are only compatible with floats.

LiftLogic Upgrade Options

LiftLogic offers Grundfos Connect as an additional option. It is a cloud based system which allows you to streamline your data and alarm monitoring right into your mobile device or PC. For an additional fee you will find peace of mind knowing what is going on with your pumps, water levels, and overall station performance.

*You may only add this option to the LiftLogic Intelligent Panel.

**If you add this option to your LiftLogic Control Panel, please allow for 2 additional days of lead time.

Bring a higher degree of reliability and protection of your equipment by adding a phase monitor to your LiftLogic control panel. These panels are already designed to handle 3-phase voltage, so adding a phase monitor will monitor incoming voltage and deenergize the equipment when the voltage is unbalanced, too high, or too low.

*Upgrade available for LiftLogic Standard Panels only.

* LiftLogic Intelligent Panels have built-in phase monitoring included.

Protect your control panel from damaging power surges. When a power surge occurs to a certain magnitude, this device will shunt that surge to ground instead to the components of your LiftLogic Panel.

Elapsed Time Meters will track the cumulative run time of each pump individually. A separate meter is assigned to each pump and will accurately measure the duration of its operation from start to stop, whether they are running in HAND or AUTO. They are durable six-digit time meters which are non-resettable.

The default enclosure on the LiftLogic is a NEMA 4X polycarbonate enclosure. As an alternative, LiftLogic panels can be built into NEMA 4X stainless steel enclosures for added durability.