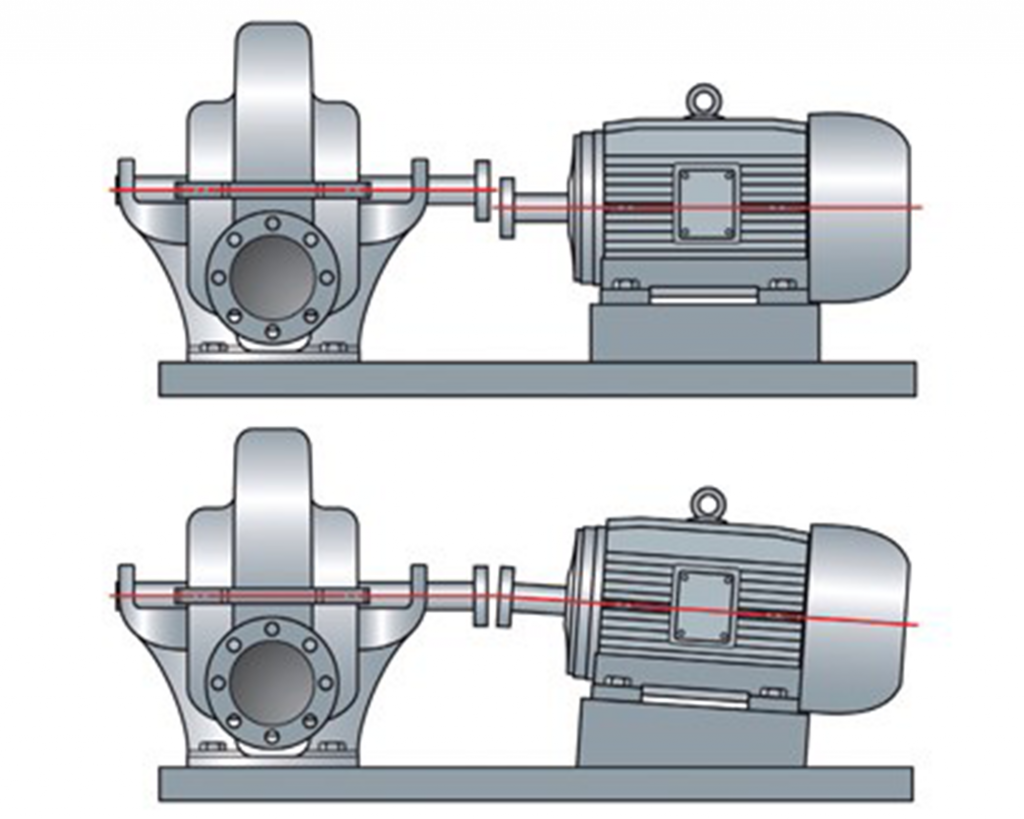

Taking care of your pump’s isolator is one way to protect the bearings, their housings, and prevent oil leakage. We previously discussed how important it is to avoid overfilling the oil cavity, as doing so can have disastrous consequences for housings, isolators, and bearings. Now, proper pump level is what we are discussing. When your pump is properly leveled, it is simple to support the proper operation of your isolator and many other pump components.

If your pump is not level, the isolator, bearing, mechanical seal (if provided), or entire system may fail. Accordingly, it is critical to use a machinist level to ensure that the X and Y axes are level. If you’re unsure how to accomplish this, please contact our pump experts for assistance. They are NCEER-certified millwrights who have installed and repaired thousands of pumps and are ready to assist you in getting your system up and running.

An inconsistent pump or motor level could be caused by a number of factors, including an unlevel pump base, a soft foot on the motor or pump, or base corrosion from a harsh environment. By ensuring that your pump and motor are level on both the X and Y axes, you can significantly improve your Mean Time Between Failure for your entire assembly, not just your isolators.

Need Expert Pump Assistance?

We offer a full range of pump services tailored to your needs. We meet you on site and inspect, install, repair, and perform routine maintenance on all your rotating equipment.