The pump impeller is the rotating part of the pump that directly transmits energy from the motor into the fluid being moved. Centrifugal pumps use one of three impeller types: closed, semi-open, and open. The best impeller for your application will depend on the fluid being pumped, the required head pressure, the NPSHa, and each system’s limitations. Considering this, it’s also crucial to keep in mind that the various impellers will affect the pump curve and alter the BEP (best efficiency point).

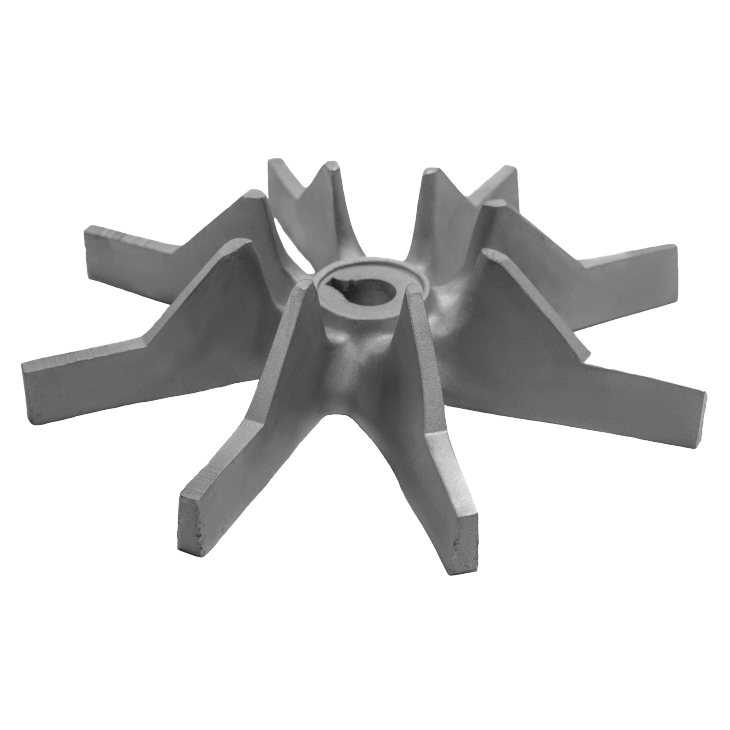

Open Impeller Design

All centrifugal pump impellers have vanes. Vanes on an open impeller are connected to a central hub, but they are not completely enclosed. This design enables fluid to freely flow through the impeller, but it may also cause some efficiency loss because the fluid can evade the vanes. In pumps that handle low viscosity liquids like raw water where the pump needs to be able to pass large solids through it easily, open impellers are indeed adopted. Due to low viscosity but higher particle density in paper stock applications, open impellers are frequently used. Thick paper stock can pass through the impeller due to its open design, thereby maintaining the flow without causing any harm or obstruction to the impeller.

Closed Impeller Design

Vanes on a closed impeller are completely encased by encircling rings, or the “back plate.” This design aids in preventing fluid from avoiding the vanes, which will lead to increased productivity and pressure. Additionally, closed impellers are frequently employed in pumps for high viscosity liquids like oils or where high pressure is essential. In water boosting applications for water treatment and wastewater treatment facilities closed impellers are used often due to the need for high head pressure. The Grundfos Hydro MPC booster system is a perfect example of using closed impellers in order to dramatically increase head pressure for water treatment. In our experience, closed impellers are the perfect choice for these applications.

Semi-Open Impeller Design

Additionally, there are shrouded impellers, which have a shroud or cover over the vanes to help direct and guide the flow of fluid, and semi-open impellers, which have partially enclosed vanes. In light of this, the semi-open impeller design can provide a compromise between the functionality of open and closed impellers and, depending on the particular requirements of the application, can provide a “best of both worlds” option for those who are forced to choose between closed and open impellers. Semi-open impellers are the most common type of impeller for centrifugal pumps because of their compromising characteristics of increasing head pressure without the risk of becoming damaged quickly.

Additionally, we advise speaking with our mechanical engineers and pump specialists to choose the ideal impeller design for your specific application. To provide the best impeller design recommendation, we will take into account the unique aspects of the application, the pump’s needed performance, and the efficiency of your system. Ready to get your project stared? Contact a GWI Pump Specialist

Need Expert Pump Assistance?

We offer a full range of pump services tailored to your needs. We meet you on site and inspect, install, repair, and perform routine maintenance on all your rotating equipment.